A Leading Manufacturer of

Forging, Casting & Precision Machined Components

Delivering high-quality solutions for a wide range of industries. With a legacy of excellence and a commitment to innovation, we take pride in being your trusted partner for all your precision manufacturing needs.

Best Manufacturer & Exporter Of Precision Machined Components

Established with a vision to be a leading precision engineering company with customer satisfaction. Our range of products used in vivid industries with on-time services makes us a reliable partner. From time to time we invest in training manpower, new machinery, and the latest gadgets to ensure we are always matching world standards with cutting-edge technologies to supply precision parts at a competitive cost.

Challenges will come every day and we are well-equipped to face them successfully with our highly knowledgeable team. Our passion to excel in every difficult task, make us unique in the industry and that’s how we succeed.

Every moment a new journey will be travelled and a new history will be created, that is how we have reached here today, and with the support of every member of the VHV family and all clients, I am highly confident that our company will continue to scale new milestones.

- OEM Approved Quality

- 100% Satisfaction Guarantee

- High Performance Components

- Professional and Qualified Staff

- Environmental Sensitivity

- Design & Development

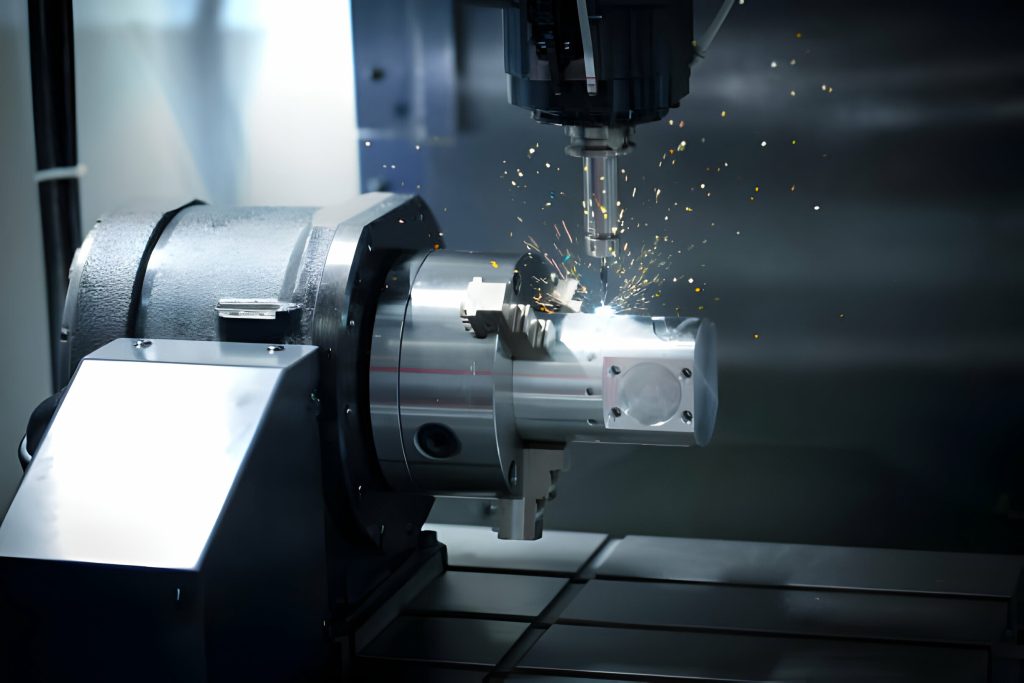

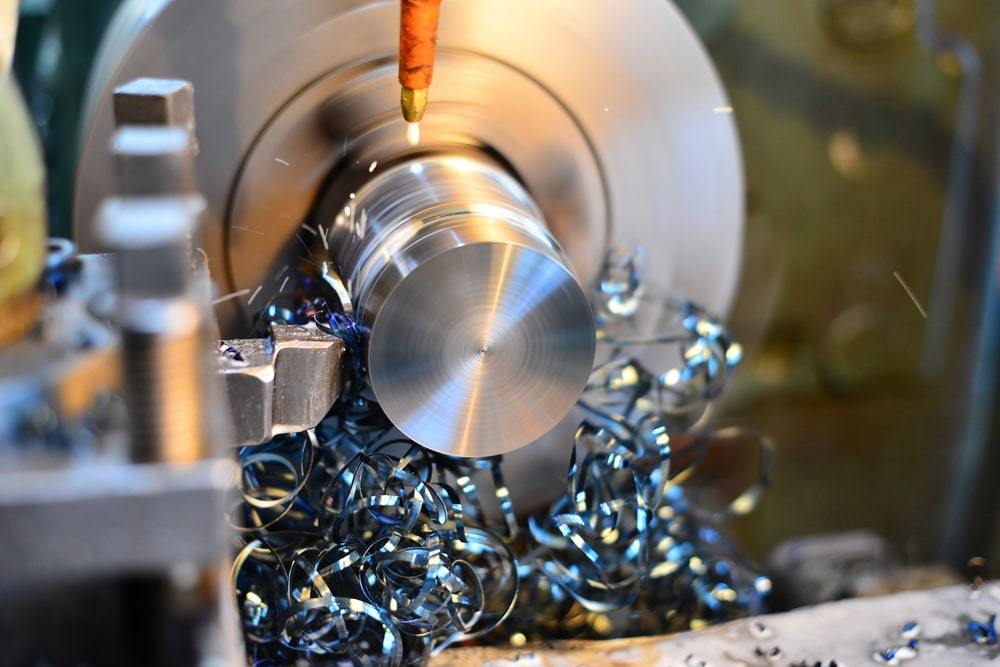

Services We Offer

Our state-of-the-art manufacturing facility is equipped with the latest machinery

forging

Shaping metal by heating it and then hammering or pressing it into a desired form. produces strong and durable components that are often used in various industries.

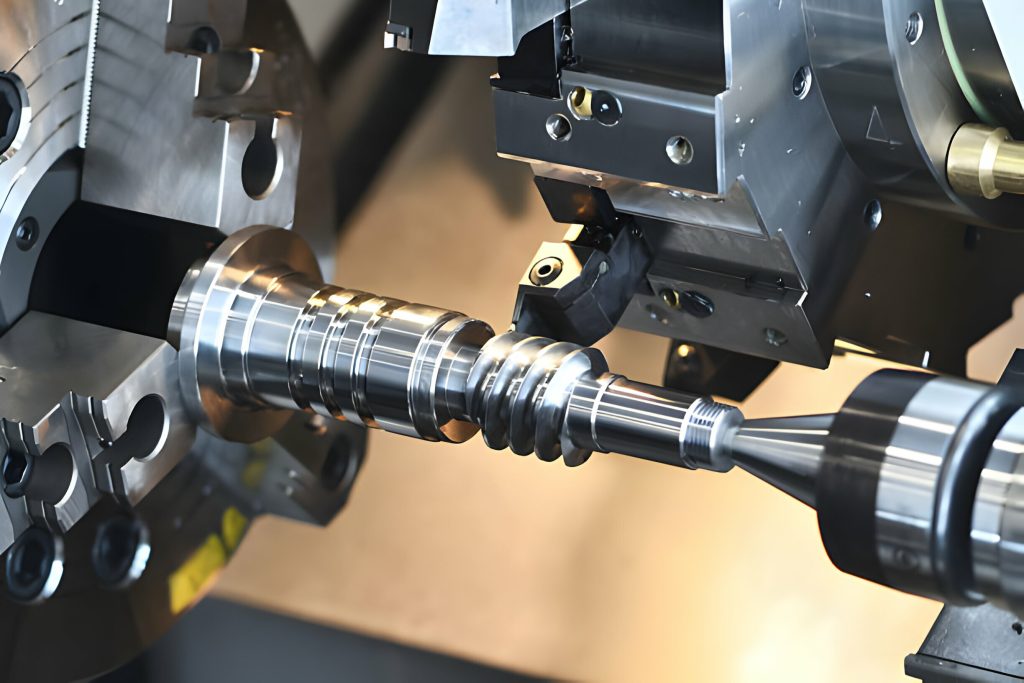

precision machining

We offer world-class precision machined parts and turned components. We use high-quality raw materials for manufacturing components.

casting

Explore our Range of High-Performance casting Solutions. Producing a wide range of parts and components across various industries.

Our Mission

To design and manufacture precision machine components that meet the highest quality standards and exceed our customer’s expectations. We strive to provide innovative, customized solutions that solve our customer’s most complex challenges while delivering exceptional value and service

Our Vision

To be a world-class engineering company known for our innovative solutions, exceptional quality, and outstanding customer service, we aspire to be a leader in our industry, delivering value to our customers, stakeholders, and employees while upholding the highest ethical standards.

Our Director's Message

We manufacture reliable solutions for many sectors and industries

We Are Open For Opportunities!

- We Are Trusted

- We Are Professional

- We Are Expert

Enabling Precise and Efficient Production of Complex Parts

Our mission is to offer professional machining service that exceed our customers’ expectations in quality, delivery and cost effectiveness.

Advanced CNC Machines

Investing in modern CNC machines with advanced features and capabilities is crucial for achieving high production rates. Look for machines that offer high spindle speeds, rapid tool-changing systems, and multi-axis capabilities. These machines can handle complex operations and reduce cycle times, resulting in increased productivity.

Process Optimization

Continuously optimizing the machining process is essential for maximizing productivity and scalability. This includes optimizing cutting parameters (speed, feed rate, depth of cut) to achieve the desired surface finish and material removal rates. Additionally, employing techniques like toolpath optimization, adaptive machining, and tool monitoring can further improve efficiency and reduce machining time.

Quality Control Systems

Implementing robust quality control systems is crucial to ensure high production rates without compromising part accuracy and consistency. In-process inspections, such as probing or non-contact measurement systems, can be integrated into CNC machines to verify dimensional accuracy during machining. Statistical process control (SPC) techniques can also be employed to monitor and control process variations, ensuring consistent quality output.

Our Core Strength

Prototype Machining

Prototype Machining

High Alloy Machining

High Alloy Machining

High Tech Facilities

High Tech Facilities

By obtaining raw materials from reliable suppliers and putting them in production under competent and trained engineers for accuracy and precision. We strive to provide our customers with the best quality components.

Our Latest Blogs

Blogs can cover a wide range of subjects, such as Forging, Casting, Precision Machining, Quality Control and Much More