CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by enabling precise and efficient production of complex parts. To achieve high production rates and scalability in CNC machining, several key factors should be considered.

Here are some important aspects to focus on:

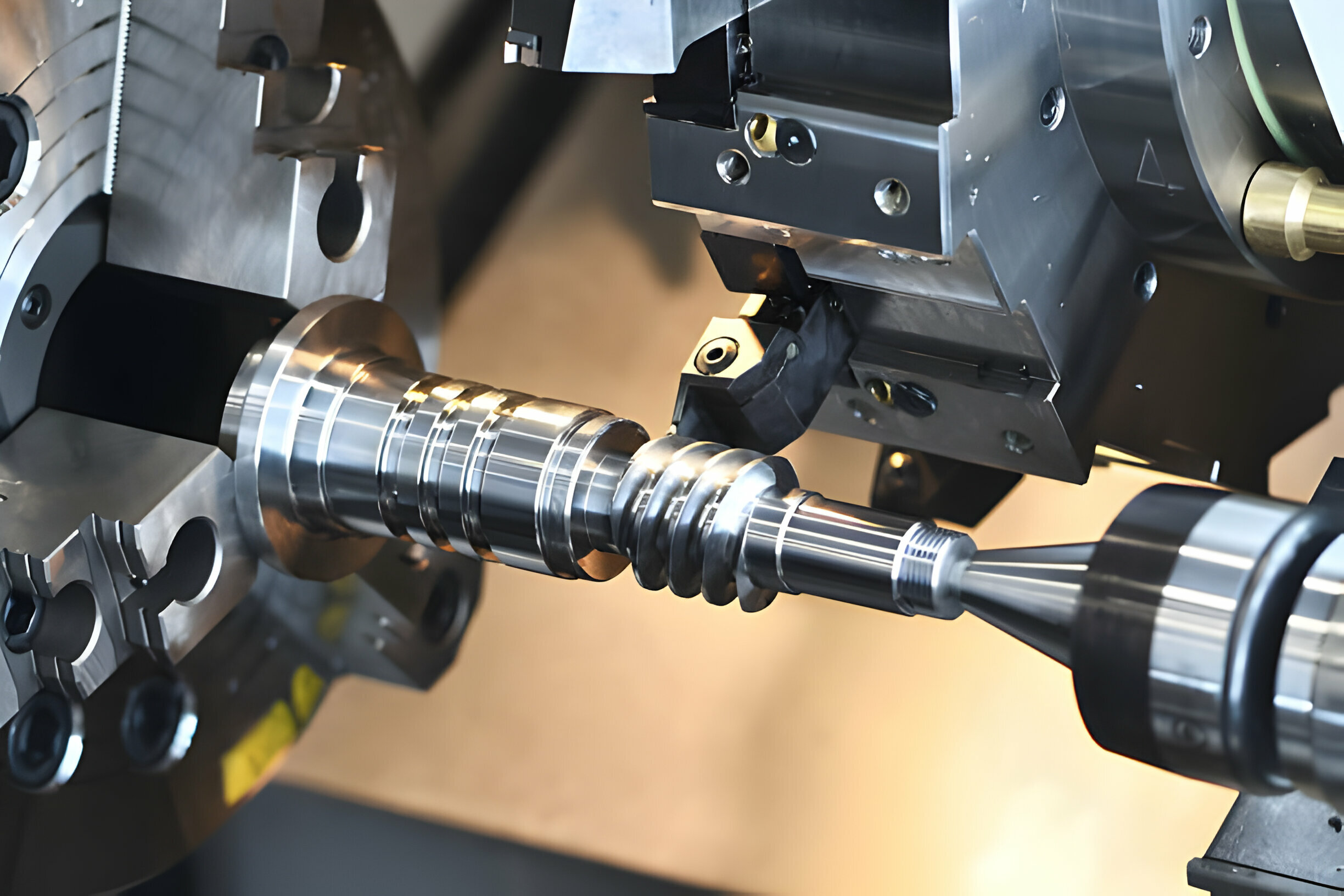

Advanced CNC Machines:

Investing in modern CNC machines with advanced features and capabilities is crucial for achieving high production rates. Look for machines that offer high spindle speeds, rapid tool-changing systems, and multi-axis capabilities. These machines can handle complex operations and reduce cycle times, resulting in increased productivity.

Automation and Robotics:

Implementing automation and robotics in CNC machining can significantly enhance production rates and scalability. Automated systems can load and unload workpieces, change tools, and perform other repetitive tasks, reducing human intervention and increasing machine uptime. Robots can work collaboratively with CNC machines, allowing for lights-out operation and

extended production hours.

CAD/CAM Integration:

Efficient CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) integration is essential for streamlining the CNC machining process. CAD software enables the design of parts, while CAM software translates these designs into machine-readable instructions. Seamless integration between the two allows for quick programming, optimized tool paths, and reduced setup times, resulting in increased production efficiency.

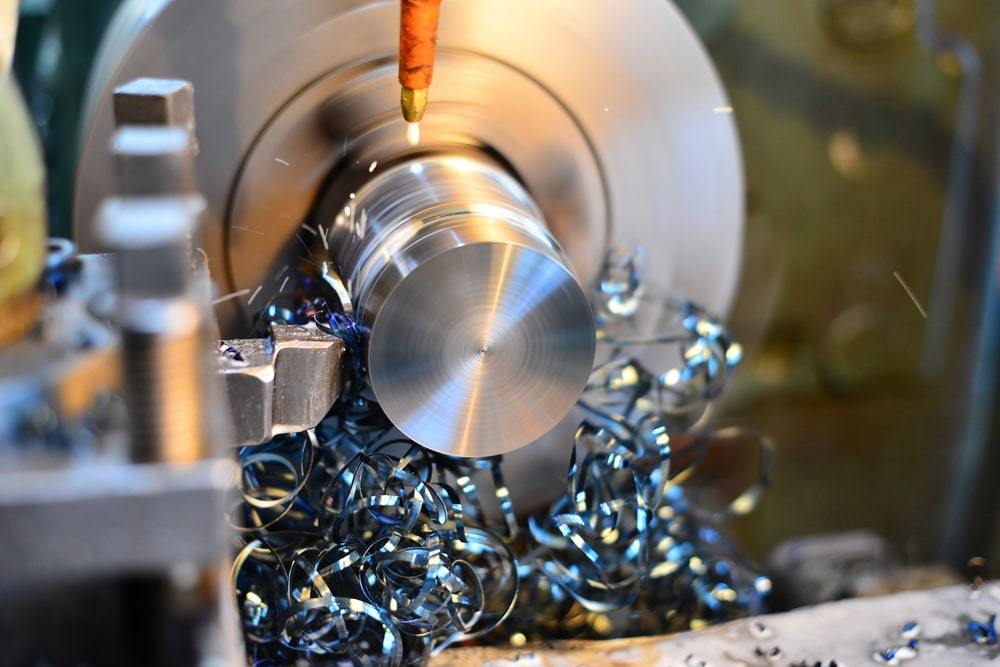

Tooling and Work holding:

Selecting the right tooling and work-holding solutions is critical for high production rates and scalability. High-quality cutting tools, such as carbide or diamond-coated tools, can increase cutting speeds and tool life, reducing downtime for tool changes. Additionally, utilizing efficient

work holding systems, such as modular fixtures or pallet systems, enables quick and accurate workpiece setup, reducing the idle time between machining operations.

Process Optimization:

Continuously optimizing the machining process is essential for maximizing productivity and scalability. This includes optimizing cutting parameters (speed, feed rate, depth of cut) to achieve the desired surface finish and material removal rates. Additionally, employing techniques like toolpath optimization, adaptive machining, and tool monitoring can further improve efficiency and reduce machining time.

Quality Control Systems:

Implementing robust quality control systems is crucial to ensure high production rates without compromising part accuracy and consistency. In-process inspections, such as probing or non-contact measurement systems, can be integrated into CNC machines to verify dimensional accuracy during machining. Statistical process control (SPC) techniques can also be employed to monitor and control process variations, ensuring consistent quality output.

Scalability Planning:

When aiming for scalability in CNC machining, it is essential to plan for future growth and expansion. This includes considering factors such as machine capacity, floor space, and workflow optimization. Scalable manufacturing systems can be achieved by implementing flexible manufacturing cells or integrating additional CNC machines in a coordinated manner.

Continuous Improvement:

Embracing a culture of continuous improvement is vital for sustaining high production rates and scalability in CNC machining. Encourage feedback from operators, monitor key performance indicators (KPIs), and seek opportunities for process optimization. Regularly evaluating and updating production strategies and adopting new technologies will help stay competitive

and adapt to changing market demands.

By considering these factors and implementing appropriate strategies, CNC machining can achieve high production rates and scalability, enabling manufacturers to meet increasing demand while maintaining efficiency and quality.