Introduction:

Precision machining plays a crucial role in numerous industries, enabling the production of high-quality components and parts with exceptional accuracy. In this blog post, we will explore what precision machining is, its importance, the key techniques employed, and the benefits it offers. Join us as we delve into the world of precision machining and discover its significance in modern manufacturing.

1. Understanding Precision Machining:

Precision machining is a manufacturing process that involves the use of advanced machinery and tools to remove material from a workpiece, resulting in precise dimensions, tight tolerances, and a superior surface finish. It encompasses a range of techniques, including milling, turning, drilling, and grinding, depending on the desired outcome and the characteristics of the material being machined.

2. Key Techniques in Precision Machining:

- Milling: A versatile technique that involves rotating cutting tools to remove material from a workpiece, often used for creating complex shapes and features.

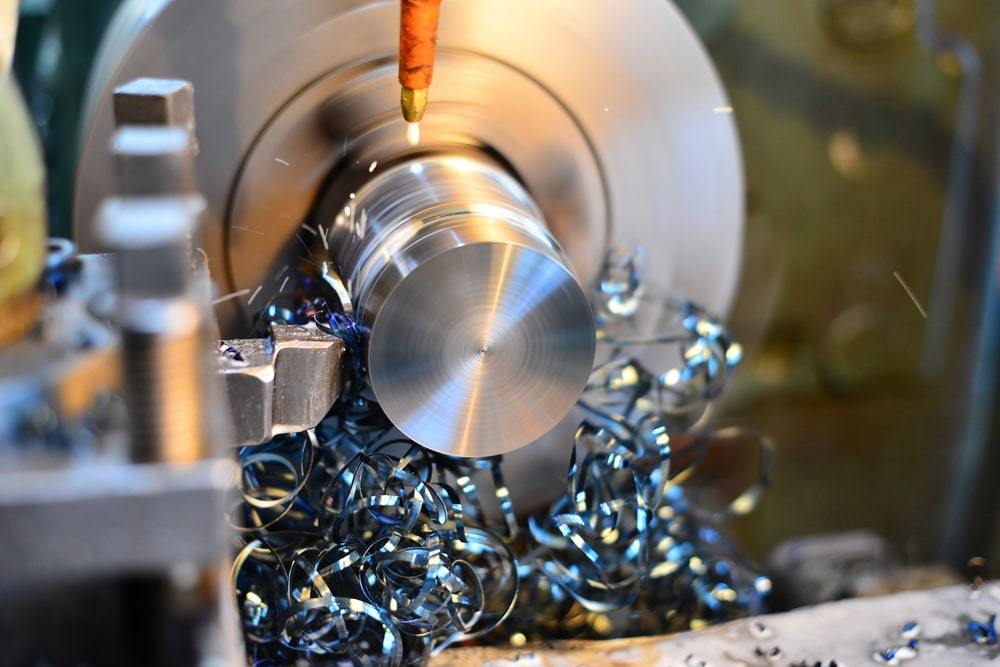

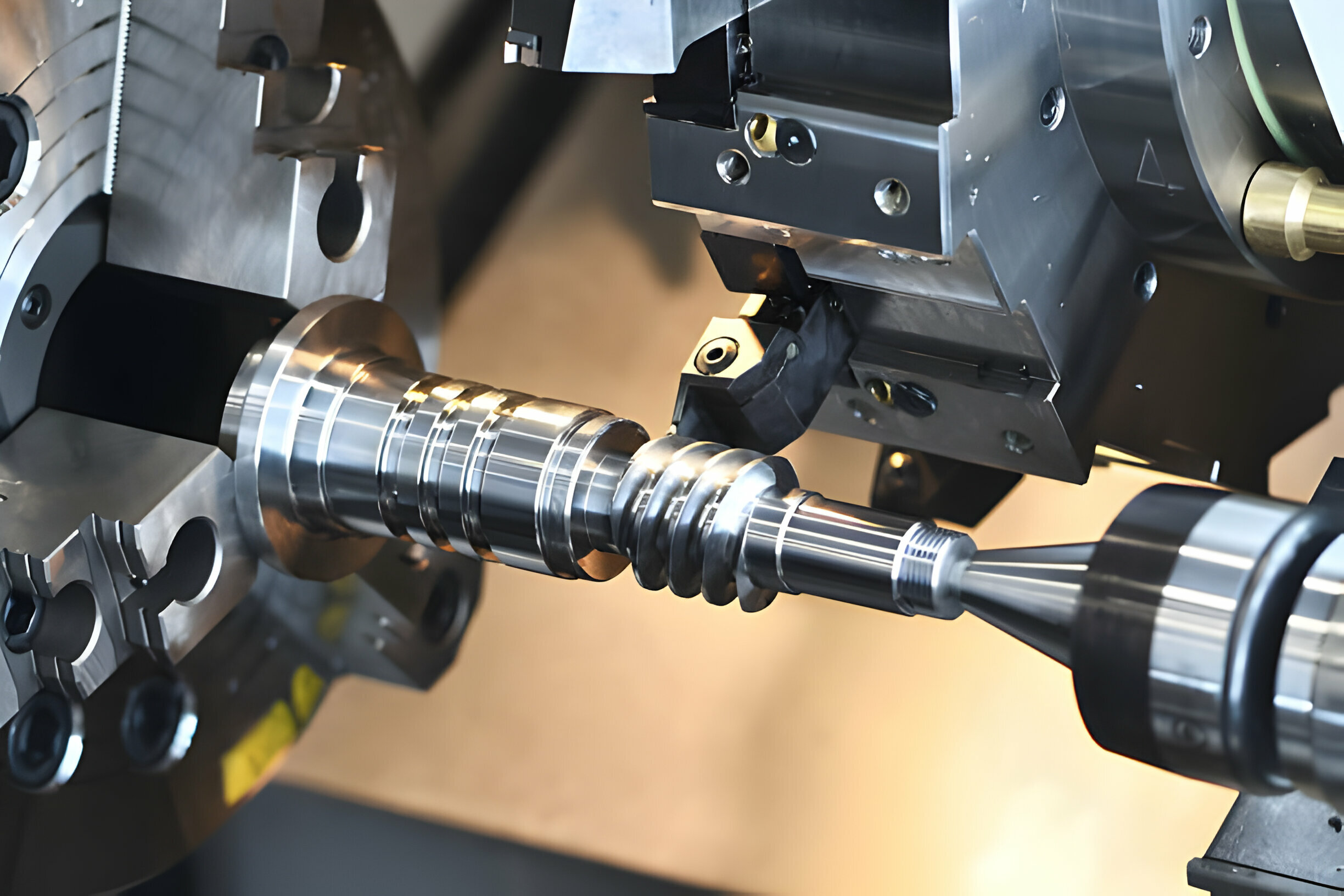

- Turning: Involves rotating the workpiece while a cutting tool removes material to create cylindrical parts with precise dimensions.

- Drilling: Utilizes rotating drill bits to create holes with precise depth and diameter in the workpiece.

- Grinding: Utilizes abrasive wheels to remove material and achieve smooth finishes, often used for precision grinding of cylindrical or flat surfaces.

3. Importance of Precision Machining:

Precision machining holds immense importance in various industries, including aerospace, automotive, medical, and electronics. Here’s why it matters:

- Accuracy and repeatability: Precision machining allows for the production of components with extremely tight tolerances, ensuring consistent quality and interchangeability.

- Complex parts manufacturing: The ability to create intricate and complex parts with precision machining is vital for industries where every detail matters, such as aerospace and medical devices.

- Enhanced functionality: Precision machining enables the creation of intricate internal features, such as threads or cavities, that enhance the functionality of the final product.

4. Benefits of Precision Machining:

- Superior quality: The accuracy and precision achieved through precision machining result in high-quality components that meet the most demanding specifications.

- Time and cost-efficiency: With the use of advanced machining techniques and automated processes, precision machining can streamline production, reduce waste, and lower overall manufacturing costs.

- Versatility: Precision machining can be applied to a wide range of materials, including metals, plastics, and composites, allowing for flexibility in manufacturing various components.

- Innovation and customization: Precision machining supports innovation by enabling the manufacturing of custom-designed parts that meet unique requirements.

Conclusion:

Precision machining is a vital process in modern manufacturing, offering unparalleled accuracy, repeatability, and quality. From creating intricate components for aerospace applications to producing precise medical devices, precision machining plays a critical role in numerous industries. Its ability to achieve superior accuracy, tight tolerances, and exceptional surface finishes ensures that manufacturers can meet the highest standards of quality and innovation. As technology continues to advance, precision machining will undoubtedly remain at the forefront of manufacturing excellence, driving progress and enabling the creation of cutting-edge products.

So, the next time you encounter a precisely machined component, remember the meticulous craftsmanship and expertise that goes into its production through precision machining.