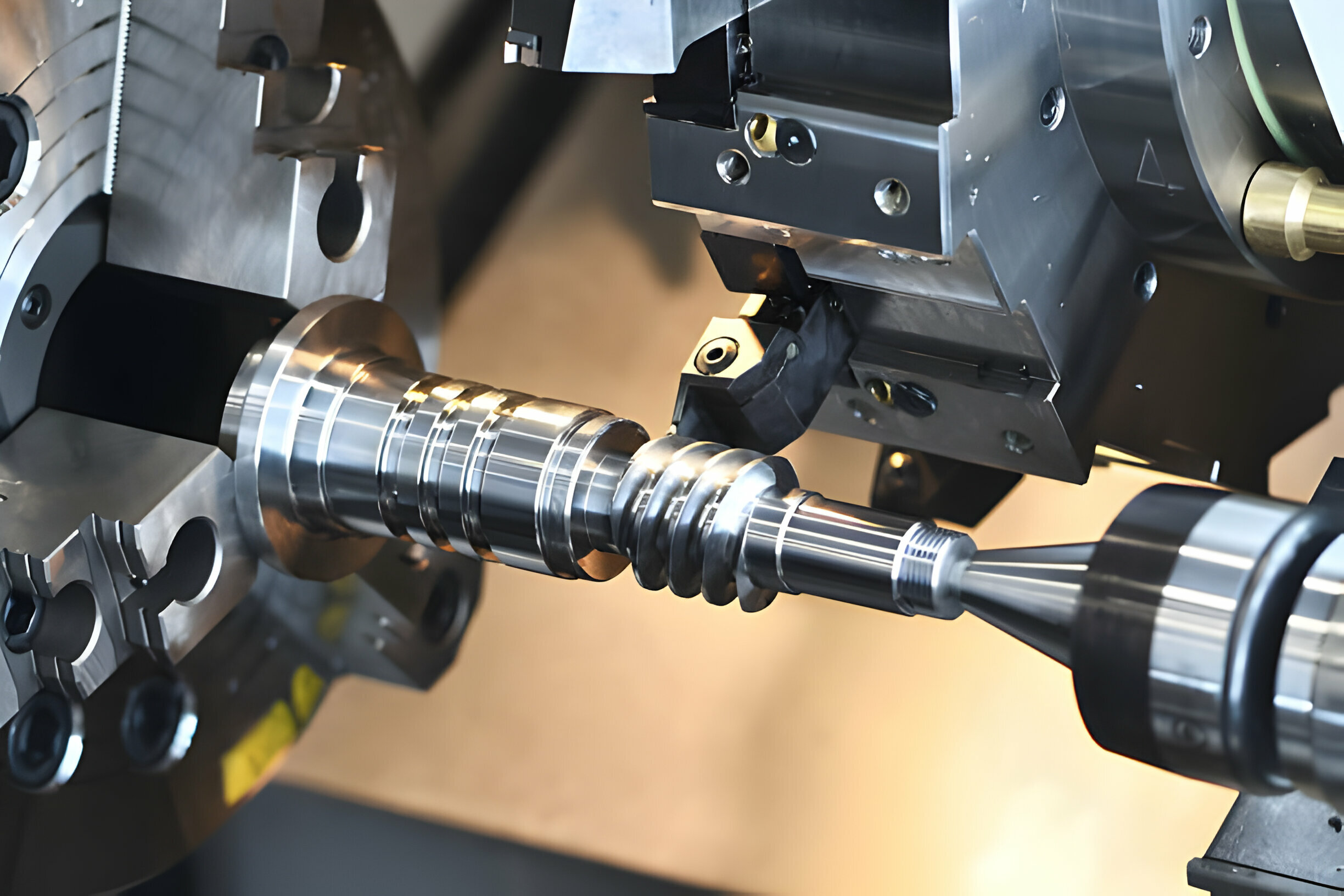

Precision machining is a remarkable feat of engineering that involves creating intricate parts and components with incredibly tight tolerances. Whether it’s in aerospace, medical devices, electronics, or any other industry where precision is paramount, the grinding process plays a pivotal role in achieving the desired level of accuracy, quality, and functionality. In this blog post, we’ll delve into the importance of the grinding process in precision machining and how it contributes to the production of high-quality components.

Understanding Precision Machining:

Precision machining involves the removal of material from a workpiece to create a finished product with extremely fine dimensions and surface finishes. This technique is used when tight tolerances and high accuracy are required, often in applications where even the slightest deviation can lead to performance issues or failure. The components produced through precision machining are essential building blocks for countless machines and devices that drive modern technology.

The Role of Grinding Process:

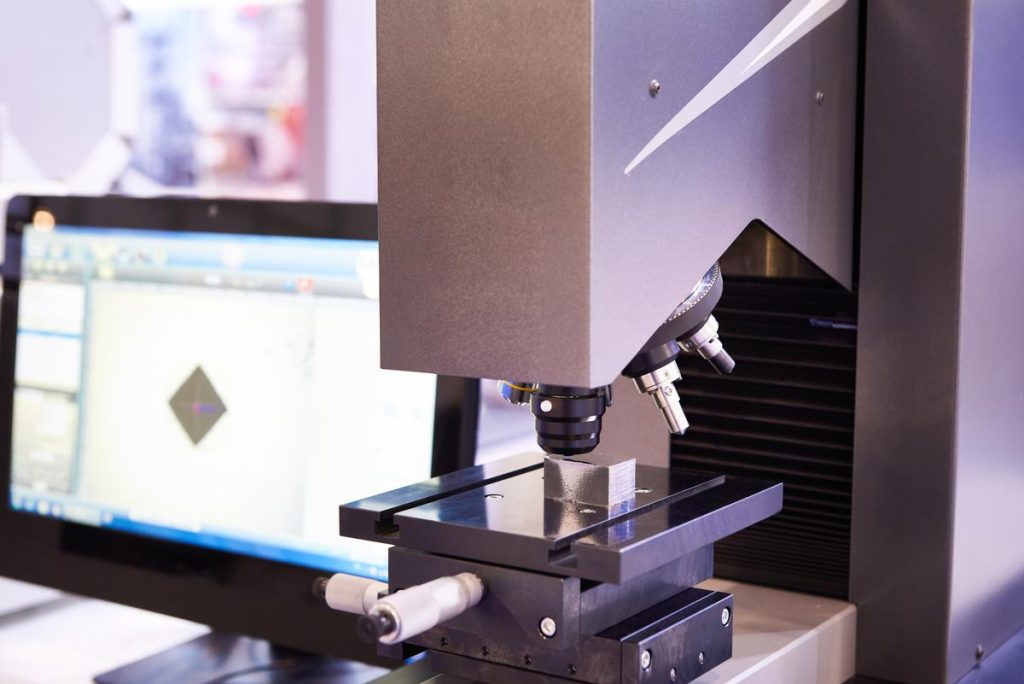

Among the various techniques used in precision machining, grinding stands out as a method that provides exceptional precision and surface finish. The grinding process involves using abrasive particles to remove material from the workpiece. Unlike traditional machining methods that utilize cutting tools, grinding employs abrasives that are harder than the material being machined, making it possible to achieve high precision even on very hard materials.

Key Benefits of Grinding in Precision Machining:

Tight Tolerances

One of the primary reasons why the grinding process is indispensable in precision machining is its ability to achieve extremely tight tolerances. Tolerances, in this context, refer to the permissible deviations from the desired dimensions. Grinding allows for precision levels measured in micrometers, ensuring that components fit together seamlessly and perform as intended.

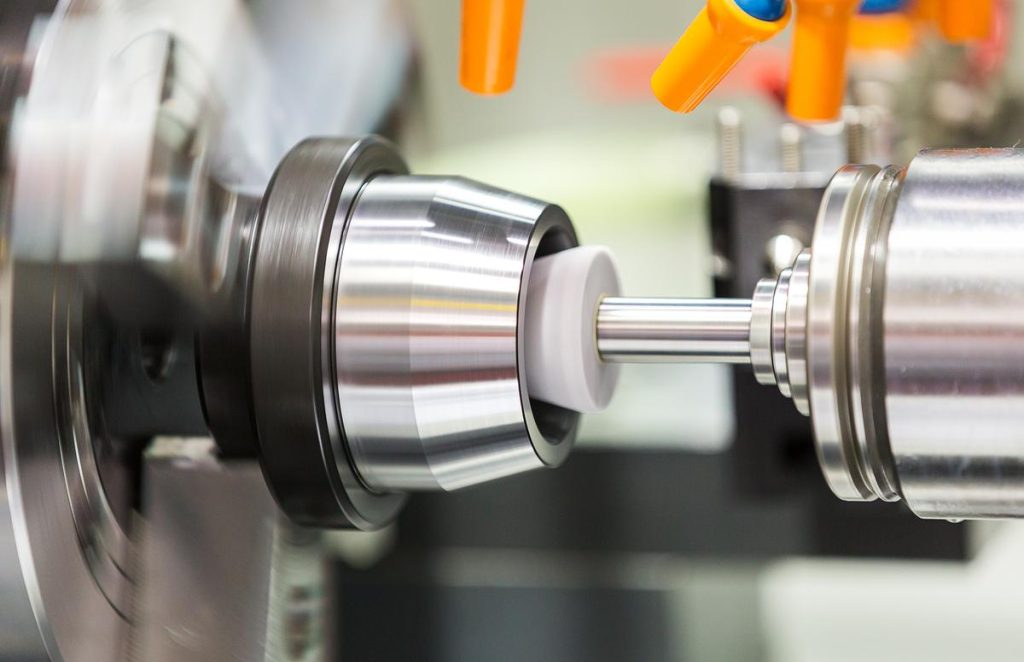

Surface Finish

The surface finish of a component is crucial in applications where friction, wear, and aesthetics matter. Grinding imparts a fine and consistent surface finish, which is essential for reducing friction, enhancing durability, and improving the overall performance and lifespan of the component.

Complex Shapes

Grinding is effective in producing complex geometries that are challenging to achieve through other machining processes. The ability to create intricate shapes with high precision makes grinding invaluable in industries like aerospace and medical devices, where unique designs are often required.

Material Hardness

Some materials used in precision machining, such as hardened steels and ceramics, are difficult to machine using conventional methods. Grinding allows for the successful shaping and finishing of such materials, expanding the possibilities of what can be achieved in terms of material selection.

Consistency and Reproducibility

The grinding process is highly controlled and repeatable, leading to consistent results across multiple production runs. This predictability is essential for maintaining product quality and meeting industry standards.

Conclusion: Elevating Precision to Perfection

Precision machining is the backbone of modern engineering, enabling the creation of components that drive technological innovation across industries. The grinding process, with its exceptional ability to achieve tight tolerances, impeccable surface finishes, and intricate shapes, stands as a cornerstone of precision machining. As industries continue to demand higher levels of accuracy and performance, the role of grinding in precision machining remains pivotal in turning complex designs into tangible, high-quality components that power our world.