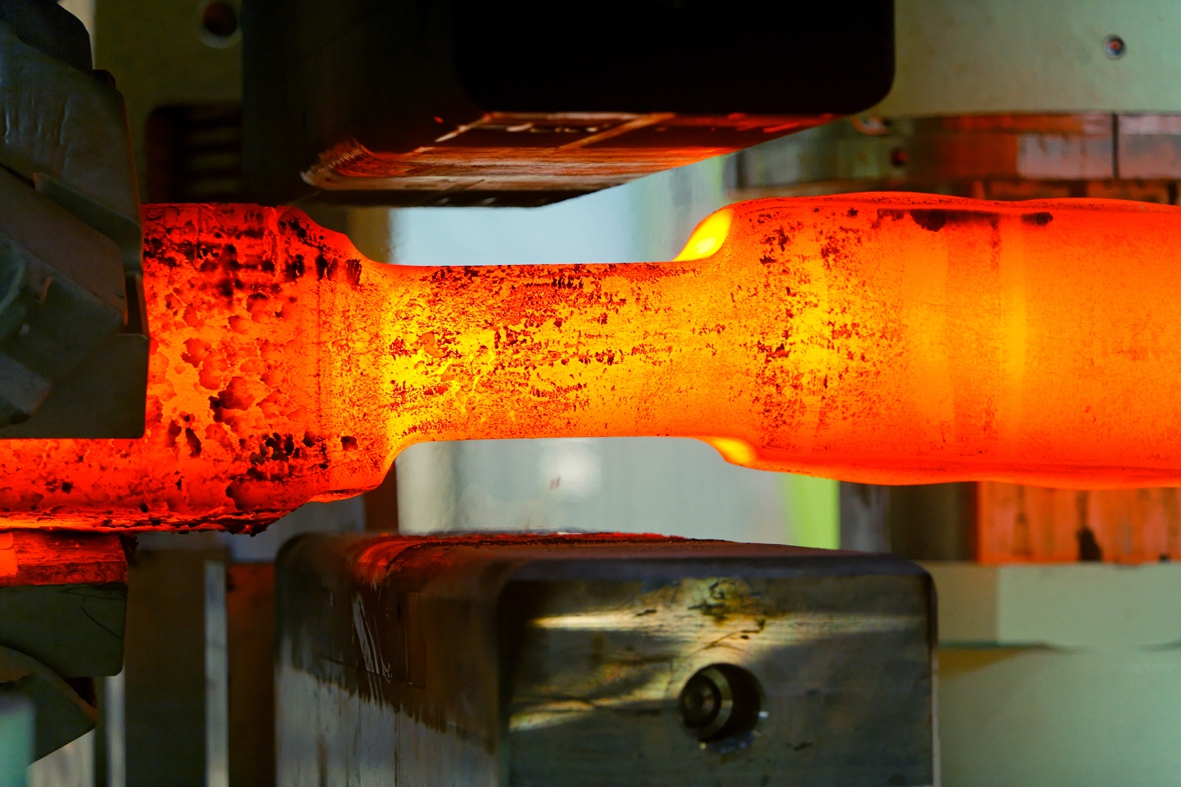

Forgings are prevalent in various industries for several reasons. Here are some of the key factors that contribute to the popularity of forgings:

Strength and Durability: Forgings are known for their superior strength and durability compared to other manufacturing processes. The forging process aligns the grain structure of the metal, making it more resistant to fatigue, impact, and other forms of stress. This results in components that can withstand heavy loads and harsh operating conditions.

Material Integrity: During the forging process, the metal is shaped and compressed, leading to improved material integrity. The elimination of internal voids and porosity enhances the structural integrity of the forged part. As a result, forgings exhibit excellent reliability and are less prone to failure.

Customization and Flexibility: Forging offers a high level of customization and flexibility in terms of part design and dimensions. It can produce complex shapes and intricate details with precision. Additionally, forgings can be created from a wide range of materials, including carbon steel, alloy steel, stainless steel, aluminum, and titanium, making them suitable for diverse applications.

Cost Efficiency: While the upfront costs of forging tools and equipment can be higher compared to some other manufacturing processes, forgings offer long-term cost benefits. The inherent strength and durability of forgings reduce the need for frequent maintenance, repairs, and replacements, resulting in overall cost savings over the lifecycle of the component.

Quality and Consistency: Forging processes, such as open-die forging, closed-die forging, and seamless rolled ring forging, involve controlled deformation of the metal under high pressure and temperature. This allows for precise shaping and ensures consistent mechanical properties throughout the forged part. The strict quality control measures employed in the forging industry help maintain high-quality standards.

Wide Range of Applications: Forgings are widely used in various industries, including automotive, aerospace, oil and gas, power generation, construction, and heavy machinery. They are employed in critical components such as engine parts, shafts, gears, valves, connecting rods, and structural components where strength, reliability, and safety are paramount.

Considering these advantages, forgings continue to be prevalent in numerous industries that require robust, high-performance components capable of withstanding demanding conditions.

looking for forging supplier? visit here https://vhvprecision.com/forging/

or email: info@vhvprecision.com, or call +91-799-290-9999 for more details.