Introduction

Drop forging is a specialized metalworking process integral to manufacturing industries worldwide. It involves shaping heated metal into desired forms using controlled hammering or pressing within dies. This method ensures superior material strength and durability, making it indispensable in applications where reliability and precision are paramount.

1. What is Drop Forging?

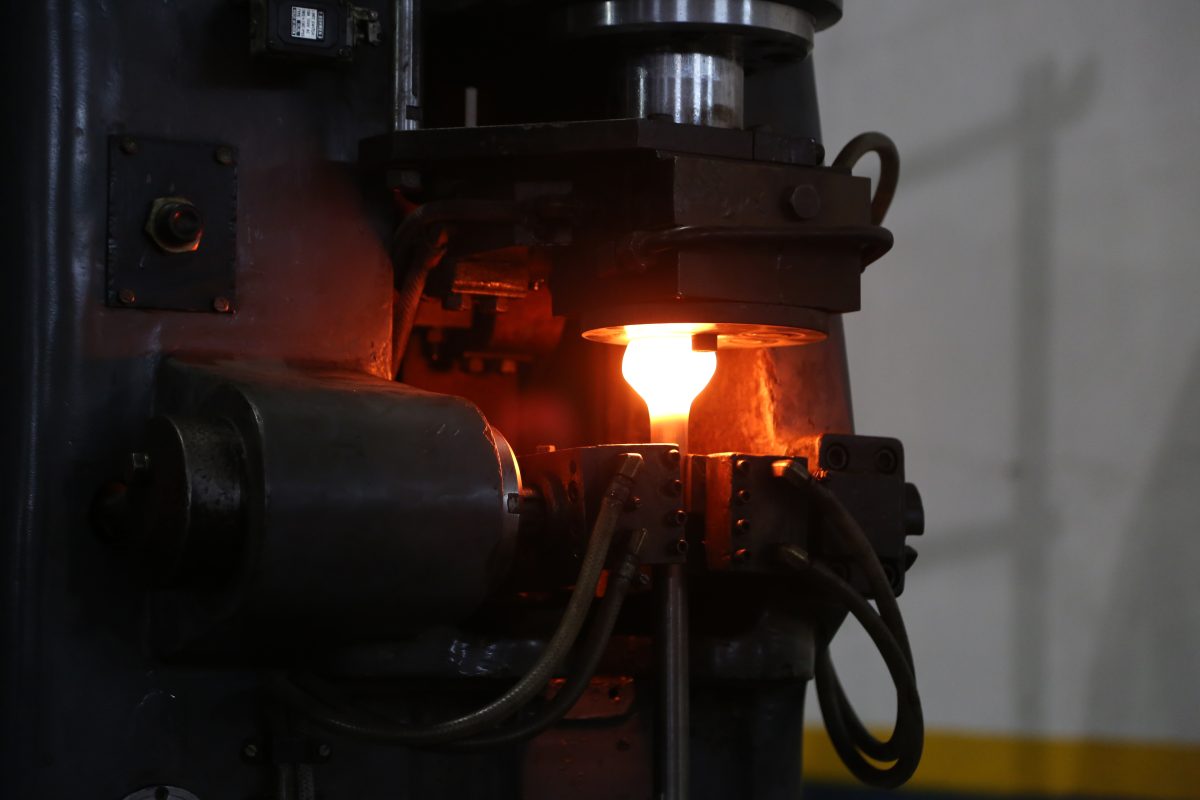

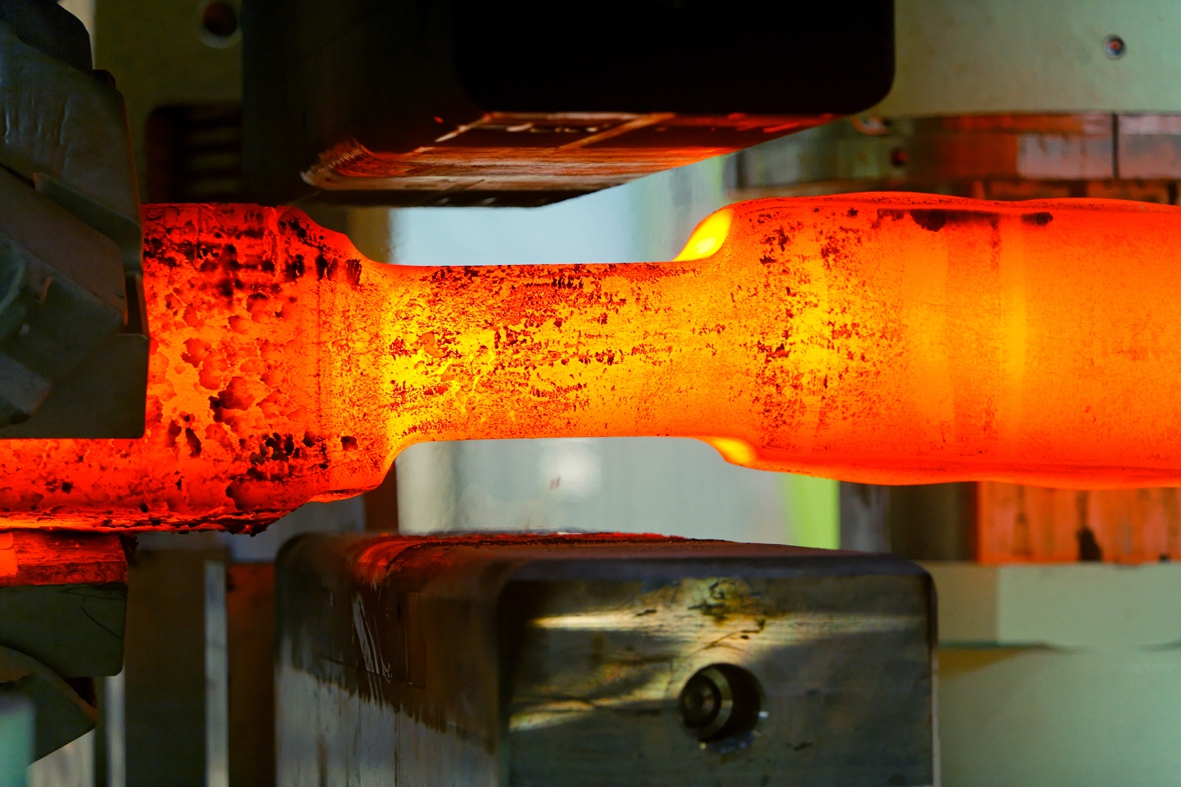

Drop forging is a forging process where a metal billet, heated to a specified temperature, is placed into a die cavity. The metal is then shaped into its final form by repeated blows from a hammer or press. Unlike casting, which relies on molten metal poured into molds, drop forging uses solid metal billets, ensuring better mechanical properties through controlled deformation and grain structure refinement.

2. How Drop Forging Works

Heating the Metal Billet: The process begins with heating the metal billet to a temperature suitable for forging. This temperature varies depending on the type of metal and its desired properties after forging.

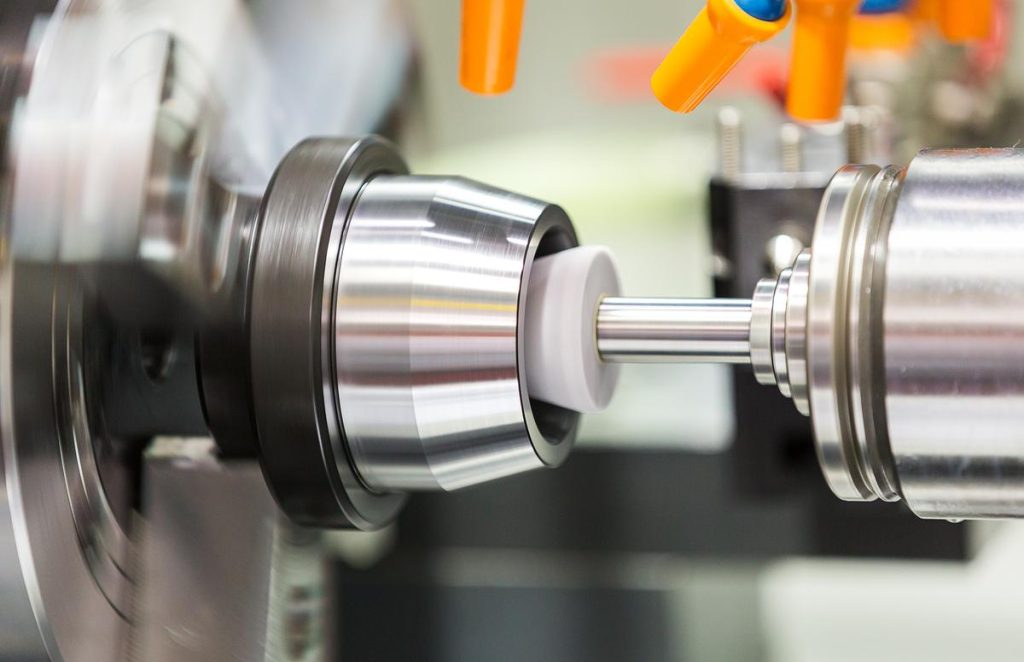

Placing and Shaping: Once heated, the billet is placed into a die cavity, which determines the shape of the final forged part. The die consists of two parts: the upper (hammer) die and the lower (anvil) die.

Applying Force: A hammer or press then delivers controlled, repetitive blows to the billet, causing it to flow and fill the die cavity. This process compresses and shapes the metal, refining its grain structure and improving its mechanical properties.

Releasing and Cooling: After forging, the formed part is removed from the die and allowed to cool naturally or through controlled cooling methods. This cooling phase helps stabilize the material and relieve internal stresses.

Advantages of Drop Forging

Drop forging offers several advantages over other manufacturing processes:

Strength and Reliability: The controlled deformation in drop forging results in superior mechanical properties, including higher strength, toughness, and fatigue resistance compared to cast or machined parts.

Cost-effectiveness: Despite initial setup costs, drop forging can be more cost-effective for large production runs due to minimal material waste and reduced machining requirements.

Complex Shapes: Drop forging allows for the production of complex shapes with precision and consistency, reducing the need for additional machining operations.

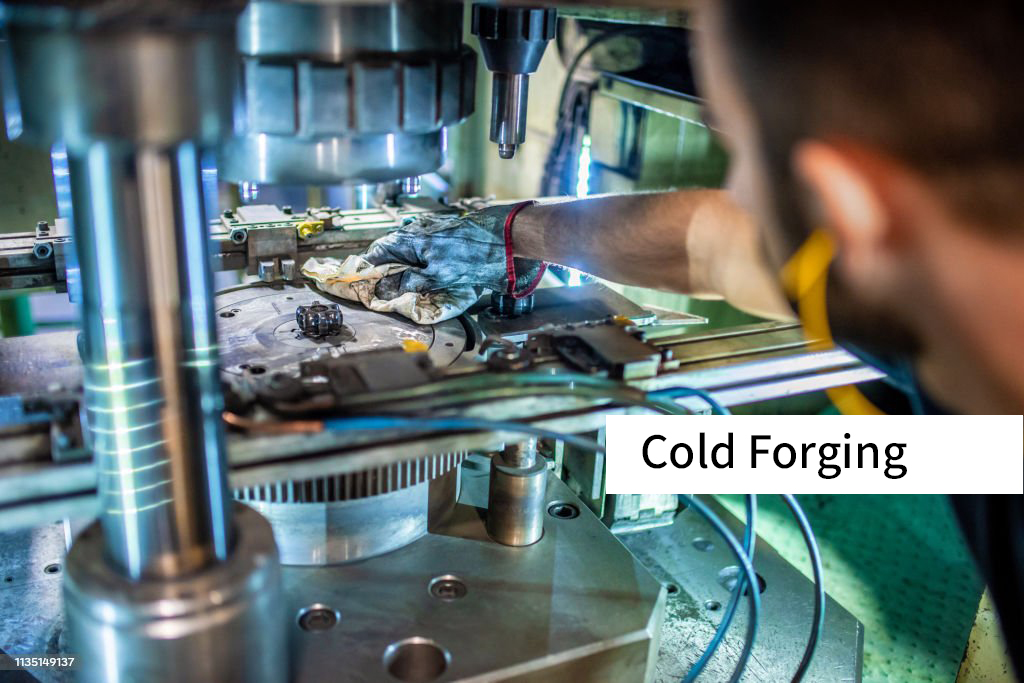

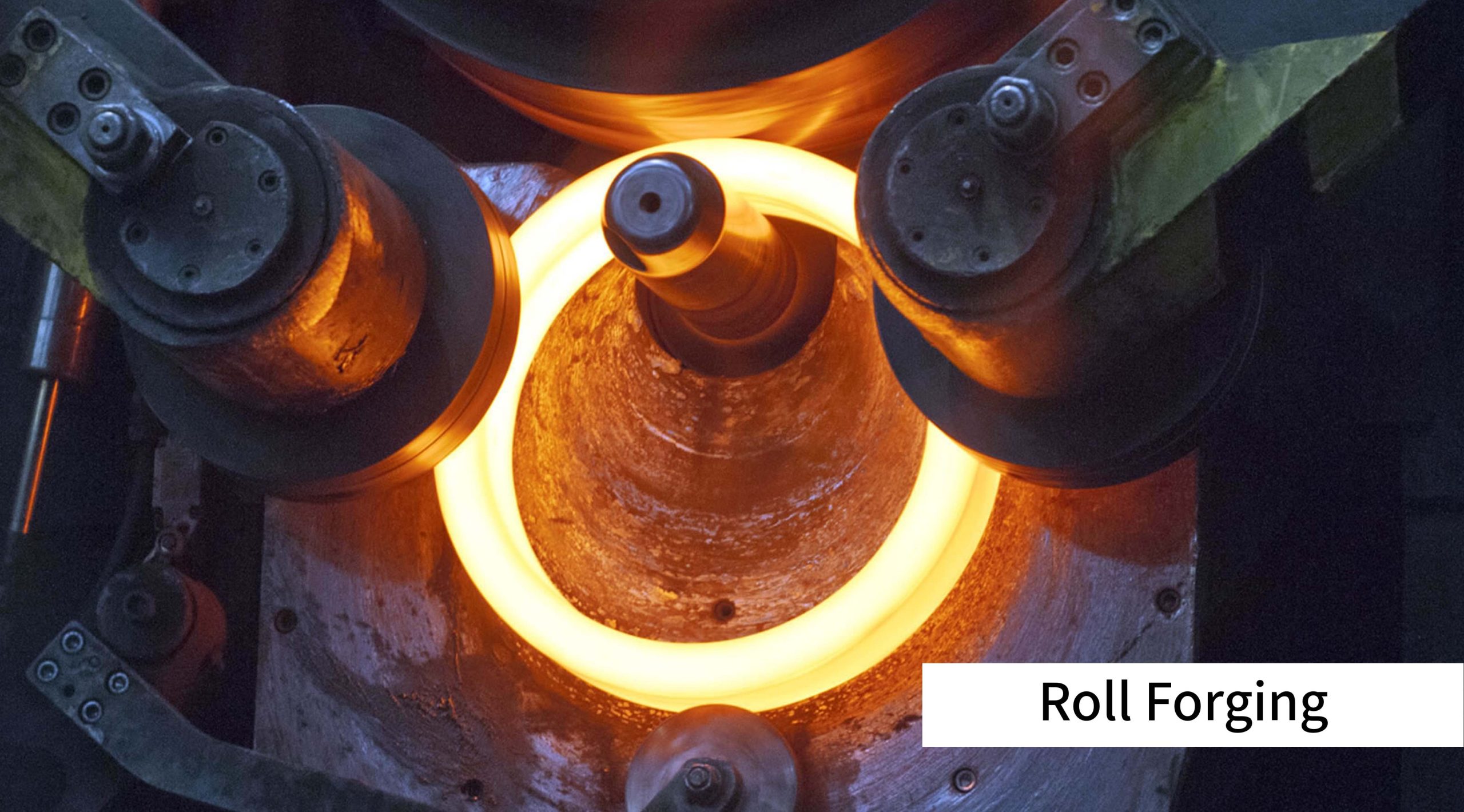

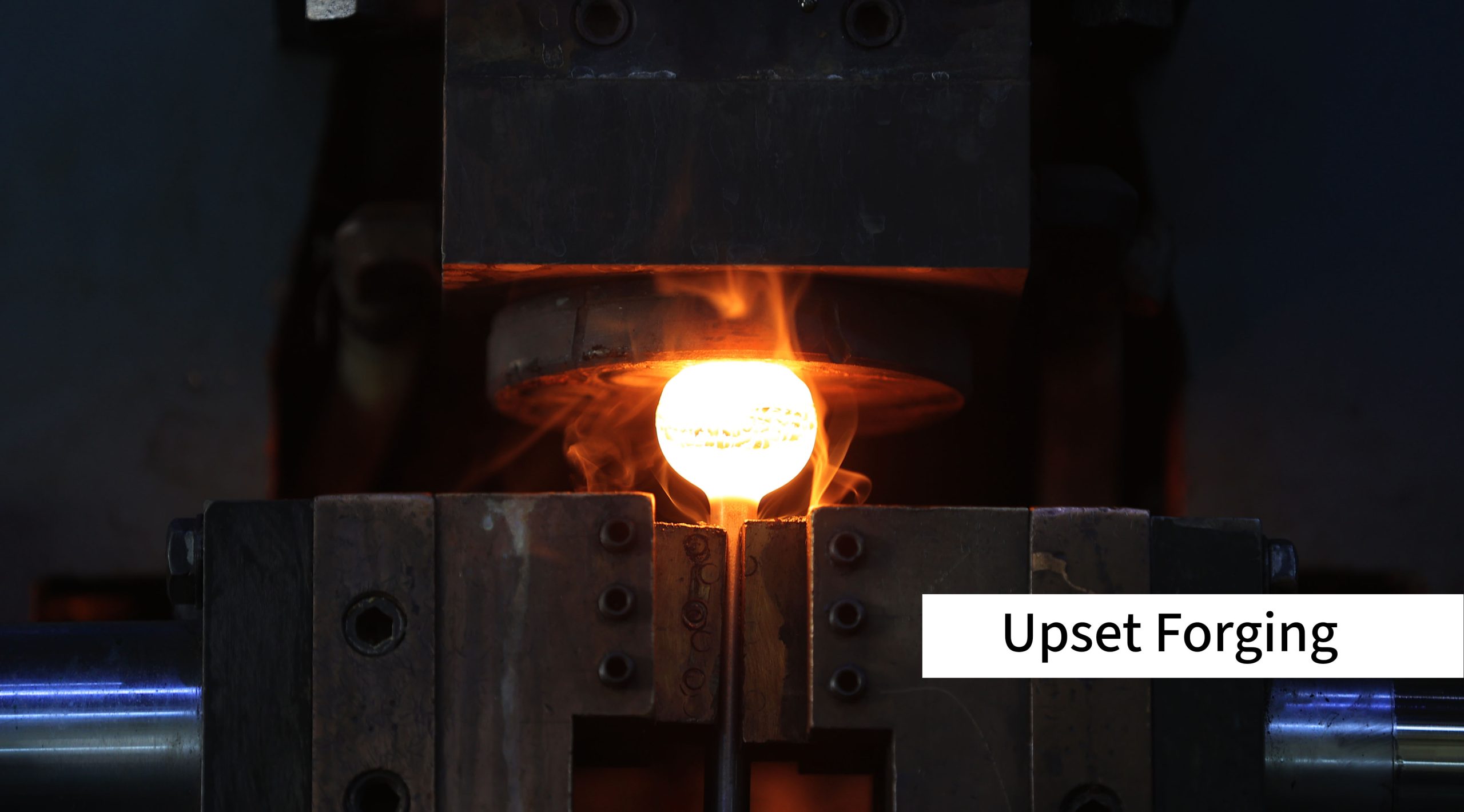

3. Types of Drop Forging

Open-die Forging: In open-die forging, the metal is hammered or pressed between flat or simple-shaped dies, allowing for flexibility in shape and size. This method is suitable for producing large components or parts with irregular shapes.

Closed-die Forging: Closed-die forging involves shaping the metal within a die cavity that contains the desired shape. This method provides precise control over part dimensions and is ideal for high-volume production of parts requiring intricate details and tight tolerances.

4. Materials Used in Drop Forging

Drop forging accommodates a wide range of materials, including:

Steel: Commonly used for its strength, durability, and suitability for various industrial applications.

Aluminum: Lightweight yet strong, often used in aerospace and automotive industries for components requiring high strength-to-weight ratio.

Brass and Bronze: Used in applications where corrosion resistance and aesthetic appeal are essential.

Titanium: Known for its high strength-to-weight ratio and excellent corrosion resistance, used in aerospace and medical industries.

5. Applications of Drop Forging

Drop forging finds applications in diverse industries, including:

Automotive: Producing crankshafts, connecting rods, and transmission components for their strength and durability.

Aerospace: Manufacturing landing gear components, structural parts, and engine components that require high strength and reliability under extreme conditions.

Tools and Hardware: Producing hand tools, wrenches, and gear components due to their high strength and precision.

6. Challenges and Considerations

Despite its advantages, drop forging presents challenges such as:

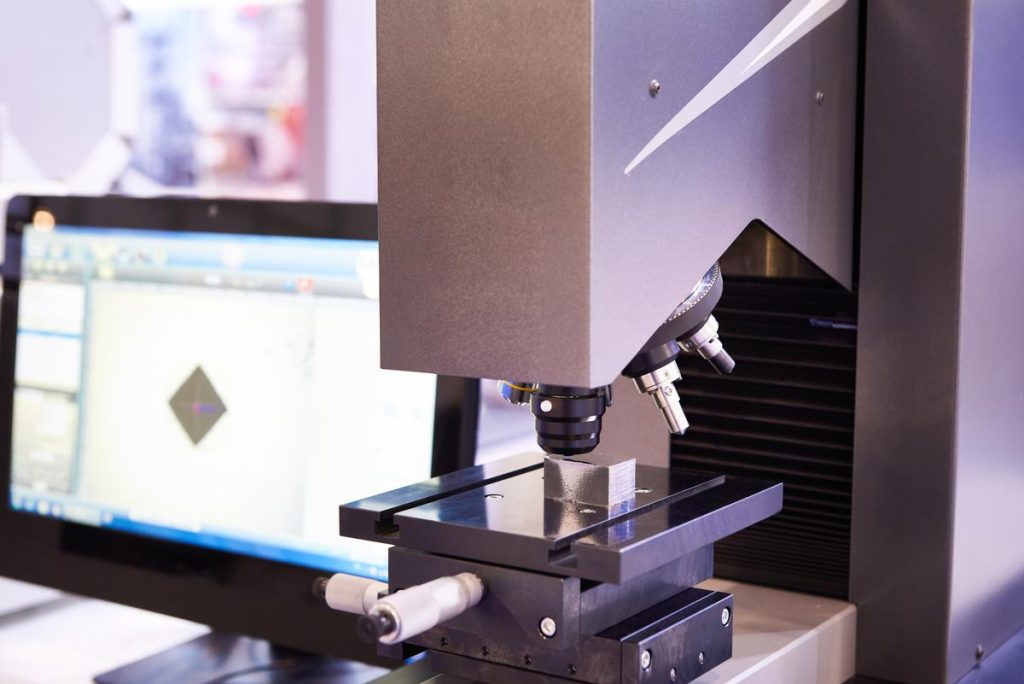

Die Design and Maintenance: Complex die designs are required for intricate shapes, necessitating regular maintenance to ensure quality and longevity.

Material Selection: Choosing the right material is critical for achieving desired mechanical properties and performance characteristics.

Energy Consumption: Heating and maintaining optimal forging temperatures can be energy-intensive, impacting operational costs.

7. Future Trends in Drop Forging

Emerging trends in drop forging include:

Die Design and Maintenance: Complex die designs are required for intricate shapes, necessitating regular maintenance to ensure quality and longevity.

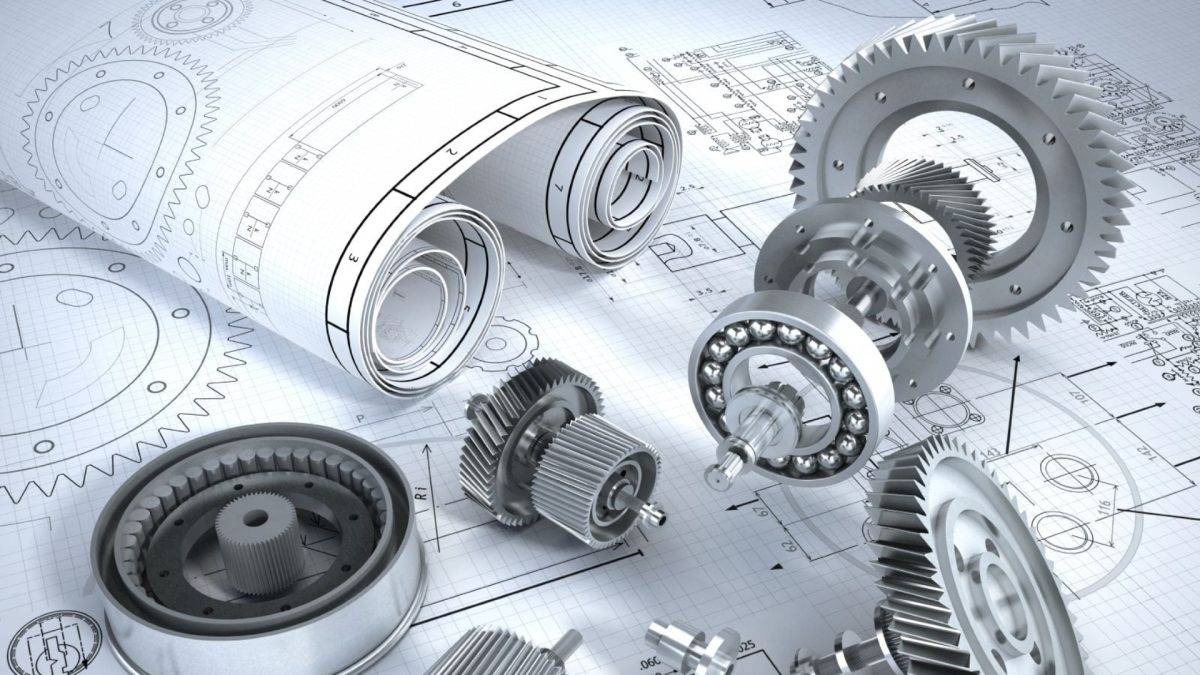

Digital Tools and Simulation: Adoption of digital tools for design, simulation, and process optimization to accelerate development cycles and improve product quality.

Advanced Materials: Development of new materials and alloys tailored for specific performance requirements, including light weighting and enhanced sustainability.

Conclusion

Drop forging remains a cornerstone of modern manufacturing, offering unparalleled strength, reliability, and efficiency in producing critical components across various industries. Understanding its principles and applications is essential for leveraging its benefits in designing and manufacturing robust, high-performance products.