Upset forging, also known as upsetter forging or heading, is a metal forming process used to increase the diameter of a metal workpiece by shortening its length. This process is commonly employed in the manufacturing of bolts, screws, rivets, and other fasteners, as well as in various automotive and aerospace components.

The upset forging process typically involves the following steps:

1. Preparing the workpiece:

A metal rod or billet is cut to a specific length, which is slightly longer than the final desired product.

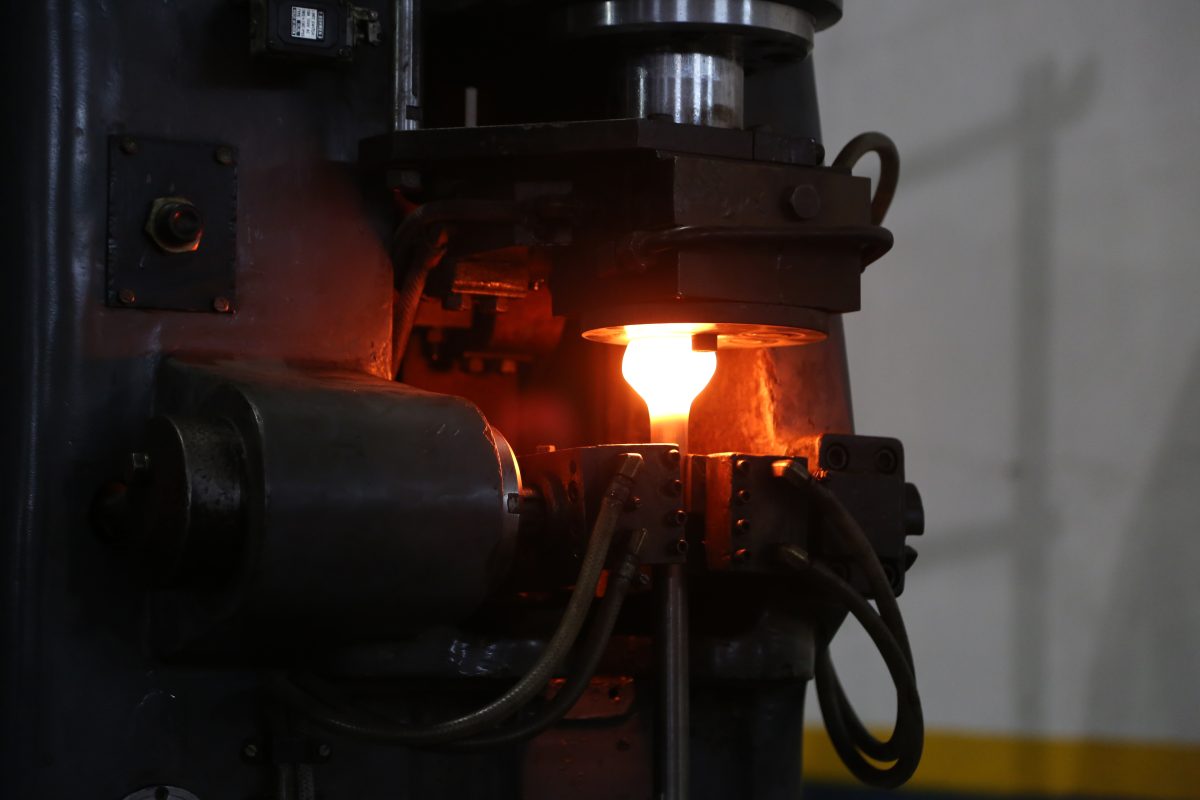

2. Heating the workpiece:

The metal is heated to a temperature where it becomes more malleable and easier to deform.

3. Placing the workpiece in the die:

The heated workpiece is then placed into a die, which is a specialized tool with a cavity that corresponds to the desired shape of the final product.

4. Forging process:

Pressure is applied to the end of the workpiece using a punch or hammer, causing the metal to flow and fill the cavity of the die. The localized compression forces the material to spread and increase in diameter while reducing its length.

5. Trimming:

Depending on the application, excess material may be trimmed or removed after the forging process is complete.

The main advantage of upset forging is that it allows manufacturers to produce complex shapes with improved mechanical properties, such as enhanced grain structure and strength. Additionally, the process is more efficient than machining or other metal-shaping methods because it minimizes material waste and reduces production time.

Overall, upset forging is versatile and widely used technique in the metalworking industry for creating strong and reliable components in an economical manner.