In a state-of-the-art era, precision machining plays a central role in developing high-quality precision-machined components for numerous industries. From Automotive to Aerospace, Medical to Oil & Gas, and Electronics to Military & Defense, precision machining is an integral part of modern production processes. In this blog post, we being the Precision Turned Component manufacturer & Precision Machining Exporter will hunt through the world of CNC Machining & Precision Machining Parts, techniques, and benefits and explore its understanding in depth.

What Precision Machining Refers to:

If been asked about Precision Machining and you are still in doubt then here’s the answer. Just as the name indicates, Precision Machining defines as shaping a raw material or any workpiece into specific and exact dimensions which also includes using blueprints generated from CAD & CAM designs.

If we briefly categories precision machining’s usage in the industries then below mentioned are few which VHV is expert in :

-

- Precision Machined Parts

- CNC Turned Components & CNC Auto Parts

- Automat Turned Components

- Agricultural Instrument Parts

- Farm Equipment Parts

- Pressure Gauge Parts

What do we mean by CNC Machining ?

To begin with, CNC represents “Computer Numerical Control” and the term CNC Machining means plays an important role in the advance world of modern manufacturing. CNC Machining holds power to computerise manufacturing process which are already pre-programmed software and its code controls the entire movement of production equipment.

Moreover, CNC Machining manages a wide range of complicated machinery and are exactly reverse of “Old School” devices which used to be manually controlled by hand wheels or levers. Today’s CNC Machines grasps and operates using machining codes like G-Code which directs machines for precise dimensions/measurements for production like speed, location, feed rate and coordination.

Now let’s understand in brief the most crucial types of CNC Machining :

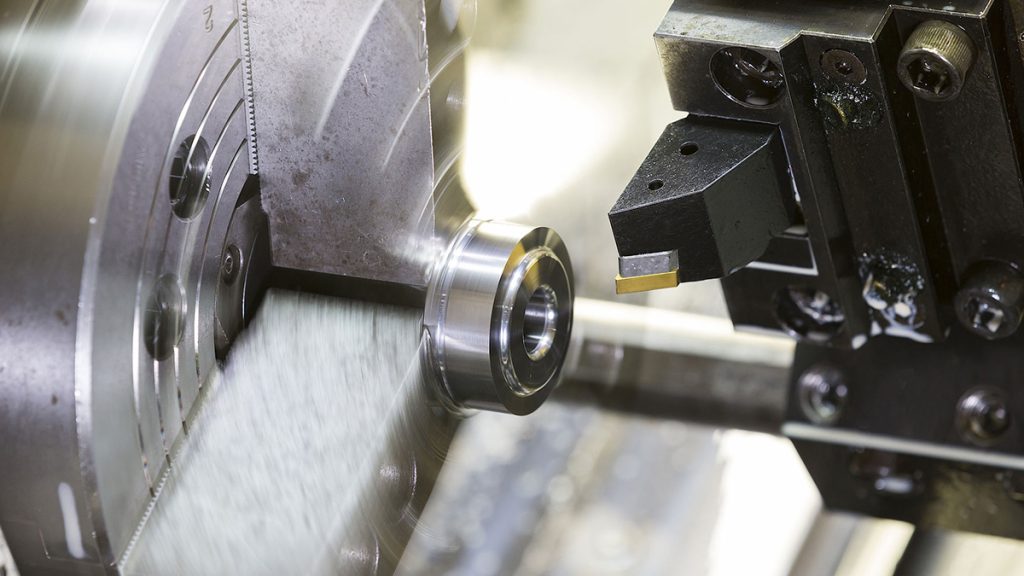

CNC Turning and Lathes Machines:

CNC Turning is a machining process which includes rotating the workpiece aligned to a rotating single point cutting tool.

Turning is said to be a “Subtractive Machining Process” which uses a cutting tool for extracting the material while creating the cylindrical parts wherein the tool itself shifts with the axis of the machined part when the part is rotarting which creates a helical toolpath. However, which explains the term “Turning” as a producing parts by cutting operations on the external surface.

Whereas with the help of Lathe Machines, the material bar slides and rotates axially through a holding mechanism into the machine and it gives better support for the material as the tooling machines. So CNC Lathe is the earliest of its kind for producing parts in a semi-automated way.

We at VHV, provide CNC Turning services which means we process largely in automated structure from Start to Finish.

CNC Milling:

CNC Milling is a subtractive fabrication technique which uses computer numerical control systems for automating the process. Thus this is a multi-point cutting tool or we can refer as milling cutter. So CNC milling machines are usually symbolised by their ability to rotate cutting tools when holding the material workpieace. So it holds power to produce wide range of shapes which includes peripheral milled features and face milled feature. Such shapes can be created in a CNC Mill enables few of the most elegant solutions to minimise engineering problems.

However, we will understand about the process, designing and setting up of CNC Mills in the coming blog post.

Grinding:

A CNC Grinding machine is also termed as CNC Grinder and is famous because it is automatically operated grinding machine. In basic terms, a CNC Grinder is a rotating grinding wheel to achieve material removal on a metallic workpiece through cutting. So, this modern generation grinding machines can be used to attain high material removal rates during the production grinding. Because it is known for its fully automatically loading facilities which is why it now terms as “unmanned operation” which brings high machining performance possible in modern manufacturing.

A CNC Grinder is made up of a spindle head which empowers the workpieces in place along with the wheels which grinds the workpieces from the sidewise or the front to accomplish a wide variety of configuration on the products which ranges from tapering, grooving, chamfering, profiling, stepping, etc on the external as well as internal radius or the diameter of the workpiece. Through this it creates the smoothest surface which finishes on the products that are ground, miniminse deformation on the products and also increases the efficiency of the grinding processes for CNC Machining Factories.

Drilling:

CNC drilling is widely implemented for bulk production. And the fun fact of the drilling machine is that it is often a multi function machining centre which at times turns and mills also. It is also rotating cutting equipment to product round holes in a stationary workpiece and these holes are developed to accommodate machine bolts or screws for assembly purposes. Therefore, the quickest machines for drilling could vary hole sizes as it has multiple spindles in turrets with drills of varying diameters which are already mounted for drilling.

If this sounds interesting to you then we could post another blog on how CNC Drilling machine Process works along with its various types.

Types of Quality Tests:

At VHV, we make sure that the quality assurance is precisely done in order to get the desired results when working with the CNC machining being the High Quality Precision Turned Component Suppliers.

Quality Inspection is an indispensable part of the manufacturing process although CNC Machining ensures higher productivity with less errors. So we are very proud to say that, at VHV all our precision manufacturing capabilities are exemplified by ISO 9001:2015. You can read about our quality assurance procedures in the coming blog post.

Visual Inspection:

It is thus very crucial for a visual inspection to be conducted because it determines whether it has been machined as needed so we make sure standard procedure is been followed by our visual inspectors on every component to maintain the standards.

Dimensional Inspection:

We ensure we manufacture the best so to maintain that level of deliverance, our state-of-art facility is such that in this modern era we use tools like Coordinate Measuring Machines commonly known as CMM which verifies each and every part features are the right dimensions and that they are correctly associated with one another.

Non-destructive Testing (NOT):

In simple terms Non-Destructive Testing is especially for using testing techniques which does not modify any other properties of already tested product. So, NDT is a testing and analysis technique used to gauge the properties of a component, structure, material or system for characteristic dissimilarity or any welding defects and discontinuities without causing harm to the original part.

So if in case we miss any internal defects in the components whilst visual inspection then we use NDT techniques such as magnetic particle inspection, ultrasonic testing, etc.

Statistical Process Control (SPC):

The main reason for implementing modern Statistical Process Control (SPC), which requires analysis and gathering of data to evaluate about the machining process whether it is most suitable for a workpicece or not, machinists can ultimately tweak reliability and quality for reducing operating costs.

Our usage of SPC Technique ensures to monitor and control the manufacturing process, determine whether the quality of the products are consistent and within the required tolerance limits.

Continuous Improvement:

For us “Good Enough “ is not enough. We want to set a bar of highest quality amongst all and to reach at that peak we at VHV believe continuous improvement is necessary and that is imposed on each and every one because it a fundamental part of our ethos.

Equipment’s use in quality testing:

- CMM (Coordinate Measuring Machine)

- Tensile Tester

- Ultrasonic Tester

- Roundness Tester

- Roughness Tester

- Couture

- MPI

- Microscope

- Hardness Tester

- Spectro Meter

- Digital Bore Gauge

Applications of CNC Precision Machining:

-

- Oil & Gas Industries

- Hydraulic Industries

- Agriculture Machinery Equipment

- Construction Equipment

- Automotive Industries

- Pump & valve

- Food Processing Machinery

- Wind energy

- Heating Elements

- Marine Industries

- Hardware

- Machinery Parts

Material Used in Precision Machining:

-

- Aluminum (Aluminum 6061, Aluminum 6061-T651, Aluminum 606, etc.)

- Stainless steel (201, 301, 303, 304, 316, etc)

- Steel (1008, 1018, 1020, etc)

- Brass (280, 260, 2680, etc)

- Copper

- Bronze

- Titanium